Lower costs versus higher risks: The dilemma of construction industrialisation

The construction industry needs to weigh up the pros and cons of using more advanced machinery with the higher fixed costs and fewer tailor-made possibilities that can limit companies’ flexibility. While such industrialisation can cut overheads, higher profit margins aren’t guaranteed

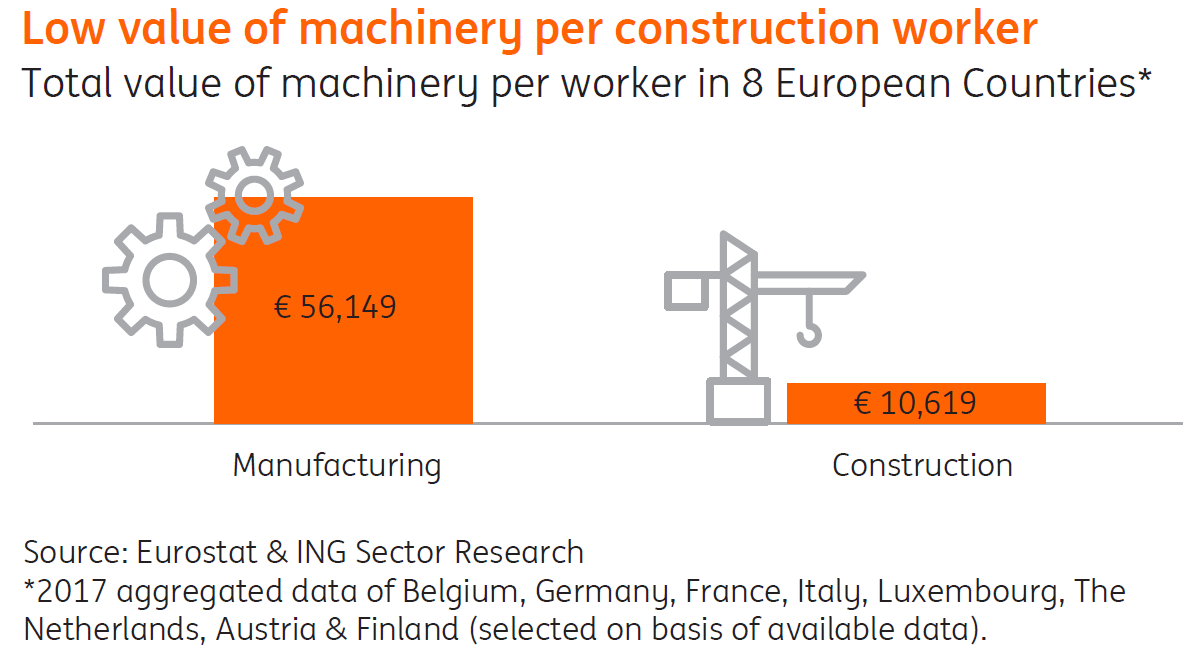

Few machines in construction

It's sometimes said that a builder often has little more than just a hammer, a screwdriver and a drill. Of course, that's far from reality but, nevertheless, construction is barely industrialised especially when you compare it to the manufacturing sector. A construction employee has approximately €10,000 of machinery at his disposal. Yet, a worker in manufacturing has more than five times (€56,000) as much equipment to work with. This limited amount of tools in the construction sector reduces productivity. An increase in the industrialisation of construction could improve the output.

That said, even though there are a lot of advantages of industrialisation, there are also important disadvantages for construction companies which have to be taken into account when they're thinking about investing.

Advantages of industrialisation

The most important benefit of industrialisation is a decrease in the building costs of about 10 to 15%. This will rise when economies of scale increase.

Industrialisation can decrease building costs by up to 15%

In addition, the demand for construction workers may decline, which can help to minimise labour shortages as people in this sector become older and retire. And industrialisation can lessen the environmental impact as there's less waste in the building process and modular industrialised building components can be more easily re-used at the end of a buildings' lifetime.

Industrialisation can also improve the quality because prefabricated construction occurs indoors in a conditioned workplace where temperature and humidity can be optimised which is important for things such as concrete curing, for instance.

But there are disadvantages

Industrialisation also has its drawbacks.

- Higher fixed costs

Industrialisation makes builders less agile, as investment in factories and machinery increases the fixed costs. This results in extra risks when demand decreases during an economic crisis. High industrialised construction companies will then have difficulties with scaling down. When output decreases, the cost level will remain relatively high due to the high fixed costs which don’t decline automatically.

- More volatile prices

Higher fixed costs can make building cost prices also more volatile. In an attempt to cover those costs, industrialised building companies can lower sales prices far below the actual cost price. They can be forced to do this to the variable cost level. As these are low, due to the high investments in industrialisation, the sales prices they are able to offer will likewise be lower. It’s a similar process that occurs for plane tickets. The variable costs of one extra passenger are almost negligible. When many seats are not sold, aircraft carriers often will lower the ticket prices to rock bottom levels.

- Fewer tailor-made possibilities

Industrialisation leads to more standardisation. Nevertheless, this doesn’t mean that only boring uniformity is possible. However, in a sector where almost every project is different, industrialisation will place some limitations on architecture. Yet, 3D-printing and robotisation can offer a solution to this. These technologies are able to produce mass customisation in which the construction of different buildings is possible along with the advantages of mass production.

Don’t start with industrialisation when you don’t have a continuous flow of orders. Your factory has to run at full capacity all the time", Ton Hillen, Heijmans

Balancing the pros and cons

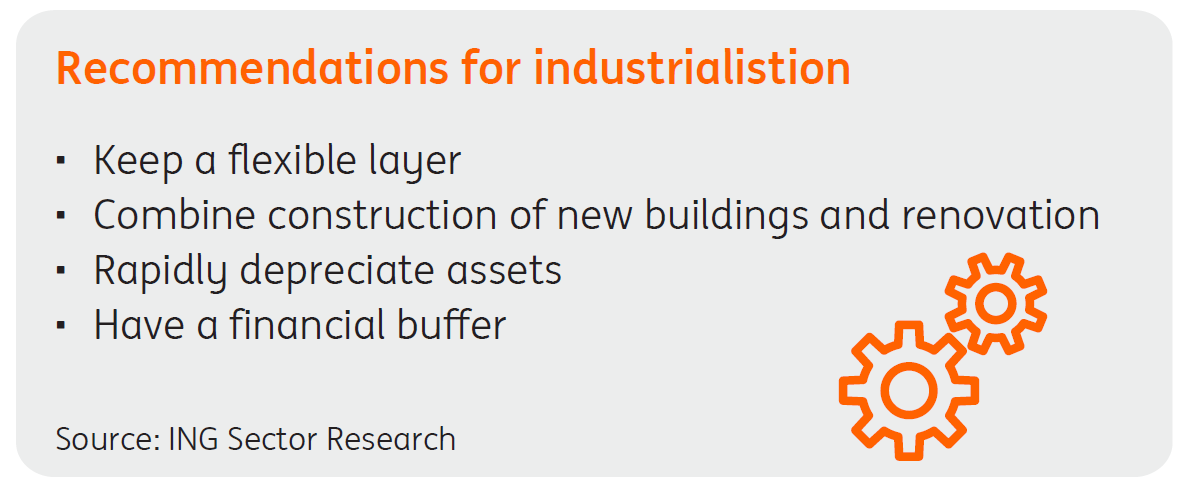

To profit from the advantages of industrialisation but simultaneously minimising the disadvantages, construction companies can take some specific steps:

- Keep a flexible layer

Building firms can choose to only partially industrialise their construction process. For instance, half the maximum production will be industrialised and the other 50% will be built in a traditional way. This means they can assure that the industrialised process can always work at full capacity, even when market demand strongly decreases during an economic crisis. Volatility of demand can be absorbed by quickly scaling up or down the traditional building process so the company stays agile and profits (partially) from the advantages of industrialisation. - Combine construction of new buildings and renovation

Industrialisation often involves new construction. However, mass customisation makes industrialisation also possible for renovation projects. Demand in this subsector is in addition not as volatile. When a construction firm combines new construction and renovation it makes itself more resilient to economic crises. In addition, it is even better if the same factory can handle both renovation and new construction assignments, so that investments costs can be minimised. - Rapidly depreciate assets

Write new equipment off quickly if that is fiscally possible, after a few years. This will result in lower fixed costs. In addition, after a few years, there may also be improved machinery. - Have a financial buffer

Lastly, industrialised construction firms can build up a financial buffer to adapt to downturns in sales when downscaling is more difficult.

The value chain: Backward integration and concentration

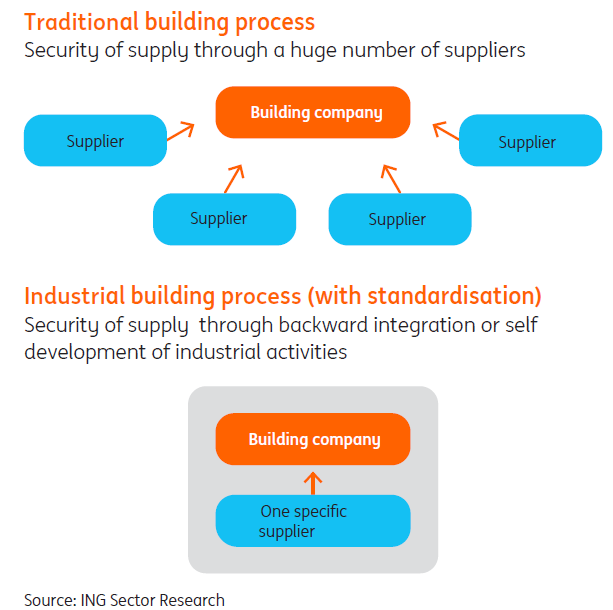

Security of supply through backward integration

Industrialisation and the additional standardisation can also lead to a changing value chain. In the traditional building process, a building company is secured by sufficient supplies and competitive procurement prices because they cooperate with a huge number of building material companies. When industrialisation increases, the number of suppliers shrink. This is due to the required standardisation of these specific building materials.

A smaller number of suppliers also leads to advantages of economies of scales when just one or a few suppliers are used. Yet, this makes an industrialised construction firm very dependable on just one supplier. And if that's the case, supply security is at risk which could place the company in a weak position during price negotiations. To secure delivery and a competitive purchase price, the industrialised building company can consider backward integration through a supplier acquisition or by developing the industrial building activities themselves.

Concentration

Industrialisation is especially beneficial when large numbers of dwellings are being produced because economies of scale can then be achieved. As a result, large industrialised construction firms will gain even more market share at the expense of smaller construction companies. Further industrialisation in construction can result in fewer but larger companies in the sector.

In-house architect

The position of the architect and constructor will likewise change when industrialisation increases. A designer has to know exactly what the industrialised construction company can and also cannot process. Design will more often than not be done in-house at the construction firm instead of at an independent architecture firm.

No long- term higher profit margins and soaring land prices

It is often thought that building companies can raise their profit margins in the long run when they industrialise and this would make the construction sector a more profitable one. Yet, we think this is misleading. Front runners will definitely profit in the beginning but an increase of competition, and landowners who will probably raise prices, will wipe out higher margins in the long run. Here's what we mean:

Front runners will profit first

Front runners of industrialisation will profit the most. When these first-movers industrialise their building processes they will have lower costs and will therefore have a competitive advantage and can, at least temporarily, increase their margins.

Diminishing prices when more builders industrialise

When more building companies industrialise the comparative advantage of the front runners will diminish. Prices will decrease due to competition and the additional profit of the front runners will disappear. In the long run, building companies’ profit margins won’t necessarily increase when more industrialisation is more common practice.

Prices of land could soar

When landowners notice that construction companies’ building costs are decreasing through industrialisation, they can increase land prices. Consequently, the total development costs of new buildings will, more or less, go back to levels seen prior to industrialisation but landowners will receive a larger stake.

Industrialisation needs consideration

So, if industrialisation apparently doesn’t lead to higher margins in the long run, building company owners could ask themselves 'why bother?'. Well, if you're a front-runner and have ambitions to stay there, higher margins are a distinct possibility.

Even more importantly, if building firms don’t industrialise to some extent they will, sooner or later, lag behind and become less competitive which can ultimately drive them out of business.

This publication has been prepared by ING solely for information purposes irrespective of a particular user's means, financial situation or investment objectives. The information does not constitute investment recommendation, and nor is it investment, legal or tax advice or an offer or solicitation to purchase or sell any financial instrument. Read more

Download

Download article